Advantages of sodium-Ion cells:

- Non-flammability

- Stable operating parameters across a wide temperature range (-30°C to +55°C)

- Long life cycle – up to 10 years

- High nominal charge and discharge currents (3C to 5C)

- Overcharge resistance

Operating Characteristics

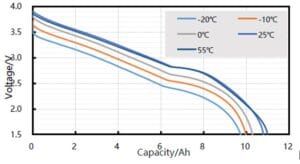

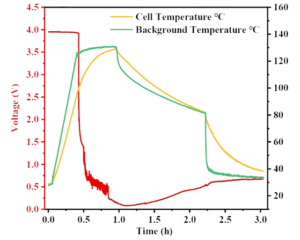

The discharge characteristics of a sample sodium-ion cell are presented in Figure 1, including the influence of external temperature.

Figure 1: Discharge Characteristics of a 10 Ah Sodium-Ion Cell

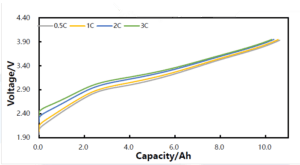

Figure 2 shows the characteristics of charging the cell with various current values.

Figure 2: Charging characteristics of a 10 ah sodium-ion cell

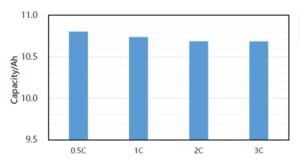

The measured capacity of cells with a nominal energy of 10 Ah for various discharge currents is shown in Figure 3.

Figure 3: Measured Capacities of a 10 Ah Sodium-Ion Cell at Different Discharge Currents

Safety Tests

The offered sodium-ion cells have undergone testing that confirms their safety and reliability.

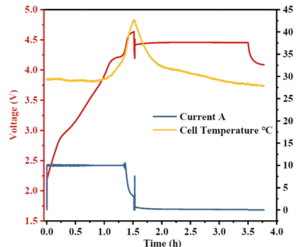

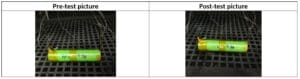

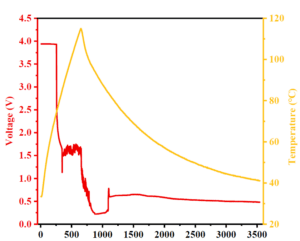

Overcharge Test

During this test, the cell is charged with a constant current of 1 C until it reaches a voltage of 4.4 V. The cell is then charged at a constant voltage of 4.4 V.

Figure 4: Overcharge Test Profile

Figure 5: View of the Cell Prepared for the Overcharge Test (Left) and After the Test (Right)

W wyniku test przeładowania ogniwo nie zapaliło się, ani nie uległo eksplozji, a maksymalna osiągnięta temperatura to 42,6 stopni Celsjusza.

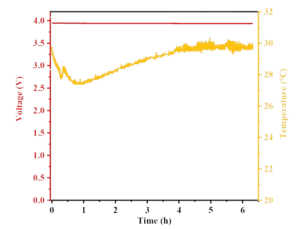

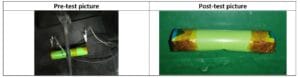

130°C Temperature Test

The cells underwent a high-temperature operation test. During this test, a fully charged cell was placed in a thermal chamber where the temperature was gradually increased at a rate of 5°C per minute from room temperature to 130°C. The temperature of 130°C was then maintained for 30 minutes.

Figure 6: High-Temperature Operation Test Profile

Figure 7: View of the Cell Prepared for the High-Temperature Test (Left) and After the Test (Right)

During the test, the cell did not explode or catch fire.

Mechanical Damage Test

The cell was tested for resistance to mechanical damage. In this test, the cell is placed on a stationary platform, and then a metal rod with a diameter of 15.8 mm and a mass of 9.1 kg is dropped freely onto the cell from a height of 610 mm. The rod strikes the cell perpendicular to the longitudinal axis of the battery and parallel to the impact surface.

Figure 8: Mechanical Damage Test Profile of the Cell

Figure 9: View of the Cell Prepared for the Mechanical Damage Test (Left) and After the Test (Right)

Cell Crushing Test

During the crushing test, the cell is placed between two plates and compressed such that the longitudinal axis of the cell is parallel to the plates. The cell is compressed with a force of 13 kN.

Figure 10: View of the Cell Prepared for the Crushing Test (Left) and After the Test (Right)

After the crushing test, the cell did not explode or catch fire, and the maximum recorded temperature was 37.2°C.

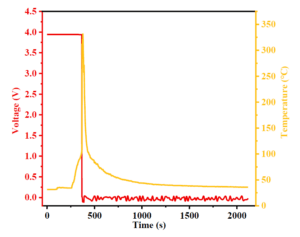

Thermal Propagation Test

During the thermal propagation test, the charged cell is wrapped with a heating pad, and a temperature sensor is placed at the top of the cell. The heating pad heats the cell with a power of 60 W until one of the following three conditions occurs:

- The voltage drop exceeds 25% of the initial voltage

- The temperature at the monitored point reaches the maximum operating temperature of the cell

- The temperature rise rate at the monitored point remains above 1°C for more than 3 seconds

Figure 12: Thermal Propagation Test Profile

Figure 13: View of the Cell Prepared for the Thermal Propagation Test (Left) and After the Test (Right)

Figure 13: View of the Cell Prepared for the Thermal Propagation Test (Left) and After the Test (Right)

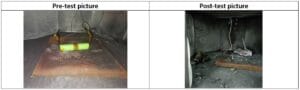

Flammability Test

During the flammability test, the cell is placed on a mesh and then exposed directly to flames. The test is considered complete when one of the following three conditions occurs:

- Cell explosion

- Complete combustion of the cell

- The flammability test duration exceeds 30 minutes without the cell igniting or exploding

Figure 14: Flammability Test Profile

Figure 15: View of the Cell Prepared for the Flammability Test (Left) and After the Test (Right)

The maximum burner temperature was 728°C. The cell did not explode during the test.

Applications

Due to their properties, sodium-ion cells are often used in the mining and extraction industries. The minimized risk of ignition and high resistance to demanding working conditions make sodium-ion cells a safe and reliable technology.