When a company invests in photovoltaic panels and an energy storage system, it expects one thing — savings. This was exactly the case with our client, who installed a 50 kW PV system along with a 100 kWh energy storage unit from an Asian manufacturer. The installation was meant to start their journey toward energy independence and significantly lower energy bills.

However, instead of cost optimization and profit, the client noticed growing, unexpected costs related to reactive power — as much as 1,900 PLN per month. It turned out that some energy storage systems offered on the Polish market not only fail to compensate for reactive power but even generate it. Although the technical infrastructure functioned properly, the inverter worked inefficiently, generating additional charges and failing to adjust the battery operation to real market conditions.

A company that must operate — eliminating unnecessary costs and maximizing energy use

Our client is a manufacturing and service company whose operations rely on a steady energy supply, and cost stability is crucial to maintaining attractive product prices.

In this case, the issue wasn’t equipment failure, but a lack of intelligent energy management. The client needed a solution that would minimize reactive power fees, enable monitoring and real-time control of the installation, and use market data and energy production forecasts. The goal was not only to avoid extra costs but also to increase returns on the investment by fully utilizing the system’s potential.

From diagnosis to action — why energy storage alone is not enough

Although the PV and energy storage systems were installed correctly, they were not delivering the expected financial results. Without an EMS system, the battery did not operate economically. Once Ennovation Technology’s software was installed, the system also showed that the battery capacity was insufficient to fully capitalize on revenue potential.

This highlights how important it is to analyze PV production and energy consumption before selecting battery parameters.

In this case, no consumption analysis or PV production simulation was performed, so the storage system was not sized optimally and the client could not fully use its capabilities.

ENNO-EMS analysis showed that insufficient storage capacity prevented optimal use of PV production.

Cost of ENNO-EMS implementation

| Item | Cost (net) |

|---|---|

| EMS Controller | 7,700 PLN |

| Integration & installation | 3,000 PLN |

| Activation fee | 300 PLN |

| TOTAL | 11,000 PLN |

Monthly cost

| Item | Cost (net) |

|---|---|

| EMS monthly fee | 350 PLN |

Monthly savings

| Source | Savings |

|---|---|

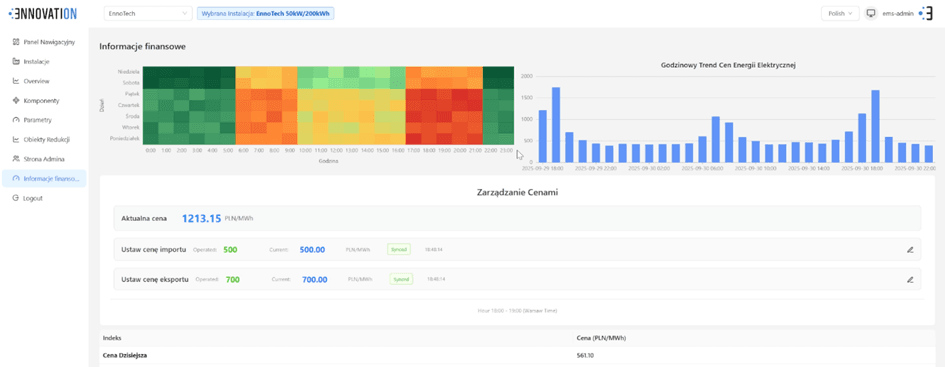

| Elimination of reactive power costs | 1,880 PLN |

| Profit from day-ahead market (RDN) | 465 PLN |

| TOTAL | 2,345 PLN |

Summary

| Metric | Value |

|---|---|

| Payback time | ~5 months |

| Monthly profit | 2,345 PLN* |

* The client could earn even more if the storage system capacity had been correctly selected.

At Ennovation Technology, we size energy storage systems based on an investment profitability analysis, for which we require:

- 15-minute consumption data

- 15-minute PV production data (if applicable)

- Sample electricity invoice

- Sample distribution invoice

With this analysis, we can help customers select proper system parameters and later optimize energy storage operation based on market conditions.

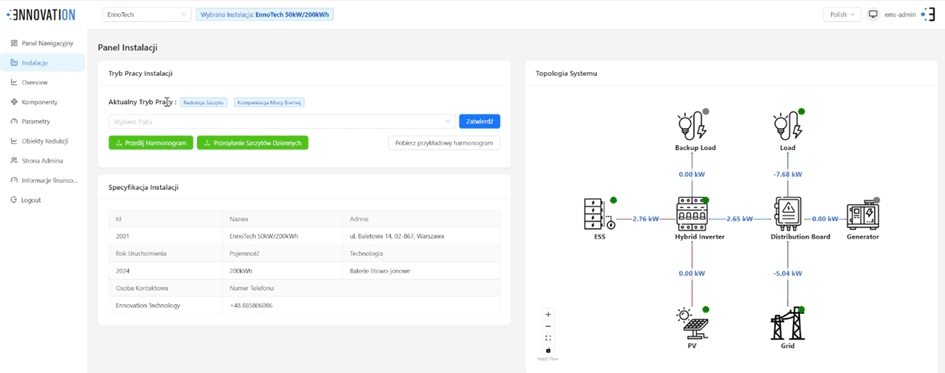

Solution: proprietary ENNO-EMS energy management system

To restore investment profitability and fully utilize the installation’s potential, we implemented our proprietary ENNO-EMS system. It took control over the inverter and battery, replacing the manufacturer’s rigid settings with dynamic, predictive control.

The software is used in SMEs, large companies, energy cooperatives, and energy clusters — and in the case of cooperatives and clusters, ENNO-EMS also supports internal settlements.

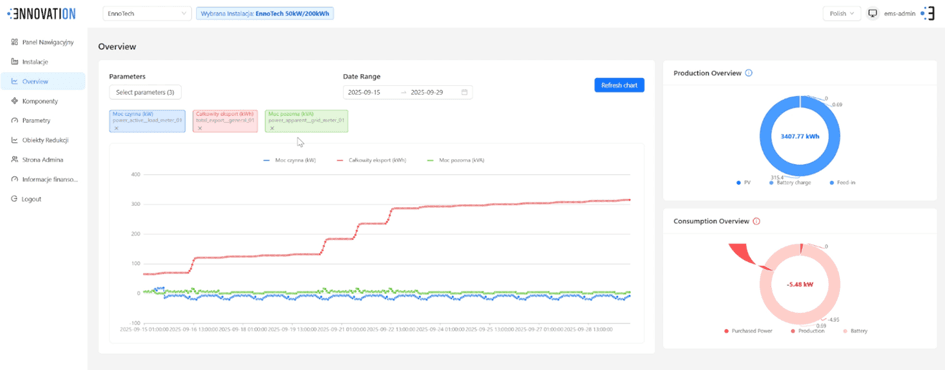

ENNO-EMS works based on weather data and solar forecasts, current energy prices on the power exchange (TGE), and the facility’s consumption profile. Using machine learning and predictive models, it plans the optimal energy usage strategy to minimize costs and maximize self-consumption and revenue from grid exports.

In practice, the battery charges during the most cost-effective periods and exports energy when prices are highest. At the same time, the EMS actively controls power quality parameters, including eliminating reactive power generation — which in this case caused 1,900 PLN in extra monthly fees.

Key insight

Even the best models cannot predict weather with 100% accuracy. Forecast error is roughly:

- ~10% for 1–2 days

- ~25% for 3–4 days

However, optimization based on weather and market data offers far greater benefits than static profiles.

Conclusion

A PV system and energy storage are often only the beginning of achieving real savings. The key is implementing an EMS system that manages, predicts, and optimizes storage operation.

With ENNO-EMS:

- reactive power costs were eliminated,

- self-consumption increased,

- full control over system operation was achieved using market, weather, and production data.

As a result, the investment paid off in just 5 months after ENNO-EMS implementation.

The ENNO-EMS controller works with almost any inverter on the market, making it flexible and future-proof. However, not every inverter supports precise power — especially reactive power — control, and response times vary by manufacturer. Advanced energy management therefore requires both high-quality software and properly selected hardware plus integration expertise.

Ennovation Technology has all the necessary expertise and supports clients throughout the decision-making process. We operate in the fields of electromobility, energy storage, EV charging (including V2G), and conversion of diesel machinery and specialty vehicles to electric or hydrogen drive.

Contact our experts:

Janusz Żyła

+48 691 104 596

j.zyla@ennovationtech.eu

Agnieszka Solarz

+48 691 104 591

a.solarz@ennovationtech.eu