The process begins with an interview with the client. Based on this, our team of engineers prepares a customized design tailored to the specific vehicle and its intended use. The design takes into account the placement of all necessary components of the hydrogen system.

Ennovation provides complete drive systems for all types of vehicles and machines, including those with hydrogen fuel cells. We are a company that enables the use of hydrogen propulsion systems in heavy-duty and specialized vehicles.

What does collaboration on hydrogen projects look like?

We focus on a comprehensive approach and partnership-based collaboration, which is why we tailor our projects to the individual needs of our clients — not the other way around. As part of our hydrogen projects, we guide the client through five main areas of cooperation.

Projects – Hydrogen drive integration, the first such project in Poland

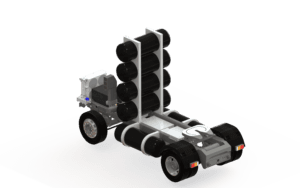

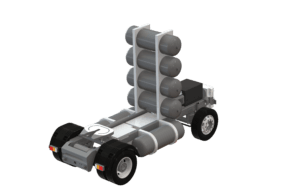

As part of our collaboration with one of the largest energy and fuel companies in Poland and Eastern Europe, we are in the process of implementing a hydrogen-powered tractor unit project (Ennovum H670). The vehicle will be prepared for long-distance transport on routes of approximately 500 km.

The Ennovum H670 is a 4×2 tractor unit with a hydrogen propulsion system. The chassis, with a wheelbase of 3900 mm, allows for optimal placement of hydrogen drive components and compatibility with most trailers. Ultimately, the vehicle is intended to be certified according to ADR regulations to allow for the transport of hydrogen in MEGC-type trailers.

Available components

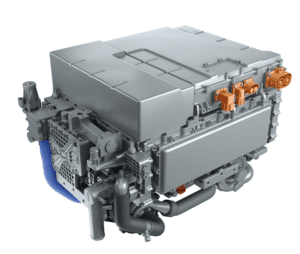

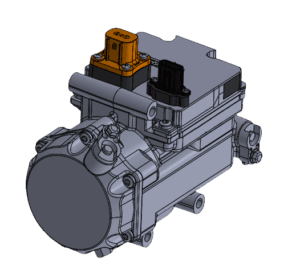

1. Fuel cell module

The main component of the drive system is a hydrogen fuel cell module with a nominal power of 140 kW and a maximum efficiency of 58%. The PEM (Proton Exchange Membrane) fuel cells are powered via an integrated BOP (Balance of Plant), which includes the hydrogen and filtered air supply systems. This setup consists of components such as an air compressor, humidifier, valves, sensors, and switches for hydrogen flow control.

The operation of the fuel cell stack is managed by an ECU (Engine Control Unit), which also monitors the system’s operating parameters to ensure safety. The byproducts of the fuel cell reaction—a mixture of air, water vapor, and a small amount of hydrogen—are discharged from the vehicle in a controlled manner.

The fuel cell module is equipped with a DC/DC converter that adjusts the fuel cell stack voltage, enabling safe operation in conjunction with other drive system components. The module also features a pump for its own independent liquid cooling system. The coolant flow and temperature are regulated by the ECU based on the amount of heat being dissipated. To maintain the proper operating temperature of the fuel cell stack, the module uses its own separate cooling circuit.

2. Compressed hydrogen storage system

Compressed hydrogen is supplied to the fuel cell module from the storage system, which consists of four Type IV tanks. These tanks are made of an inner layer of HDPE (High-Density Polyethylene) wrapped with a composite reinforcement made of carbon fiber. The system’s nominal pressure is 700 bar. It is located behind the driver’s cabin. The total mass of gas stored in the system is approximately 49 kg, providing the tractor unit with a range of around 500 km when towing a trailer.

The compressed hydrogen storage system meets the requirements of UN ECE Regulation R134.02, which outlines safety guidelines for hydrogen storage systems in vehicles. Each tank is equipped with an OTV (On-Tank Valve), which allows hydrogen to be delivered to the fuel cell stack, refueled during filling, and vented in case of an emergency. The tank set includes TPRDs (Thermal Pressure Release Devices) that release hydrogen in the event of a sudden temperature rise inside the tanks. Refueling is done via an H70 connector located behind the driver’s cabin.

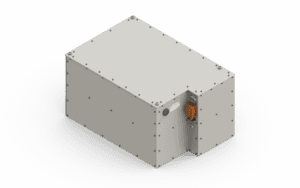

3. Battery system

The Ennovum H670 tractor unit is equipped with our proprietary battery system, which stabilizes the operation of the fuel cell stack, supports power delivery during high-demand situations, and enables energy recovery—for example, during braking—thus improving the overall efficiency of the vehicle. The batteries are equipped with a liquid cooling system, allowing optimal operating conditions for the lithium-ion cells. This not only helps maintain high battery performance but also extends their lifespan, as the cells are protected from high temperatures that accelerate degradation.

The integrated BMS (Battery Management System), in addition to basic cell monitoring and management functions, also features thermal runaway and thermal propagation detection capabilities, as required by the newly enforced UN ECE R100.03 partial type approval regulation. The use of advanced battery monitoring systems ensures a high level of device safety.

The battery system can be charged from an external power source via a standard CCS2 connector located behind the driver’s cabin. AC charging is possible with an onboard charger rated at 22 kW, taking approximately 6 hours. DC fast charging is also supported, with charging times of about 1 hour at a power level of 150 kW. Thanks to this setup, the vehicle can travel a limited distance in battery-only mode without using the fuel cell module.

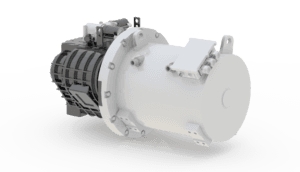

4. Electric motor and integrated transmission

Power from the electric system is delivered to the wheels via a centrally mounted electric motor with a continuous power output of 360 kW and a peak output of 500 kW. The motor is integrated with a 4-speed transmission, which allows for maximizing the efficiency of the drive system depending on current driving conditions.

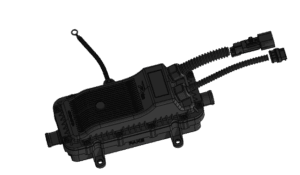

5. Vehicle controller

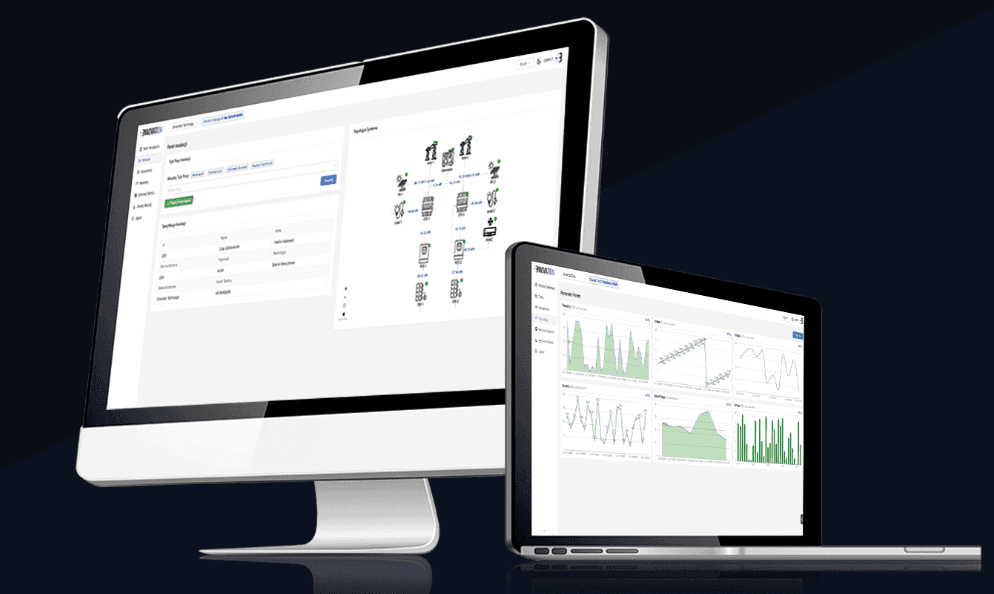

Our proprietary charging controller manages the entire vehicle. At Ennovation, we are responsible for both the hardware design and the software, allowing us to seamlessly integrate all components, adjust vehicle parameters according to customer requirements, and implement the desired functionalities.

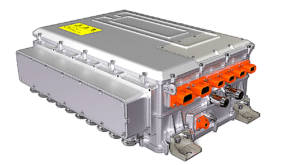

6. Integrated power electronics

A comprehensive power electronics module designed for modern drive systems based on hydrogen technology. This solution integrates all key components needed for efficient energy management in the vehicle, simplifying system architecture while reducing installation space and overall weight.

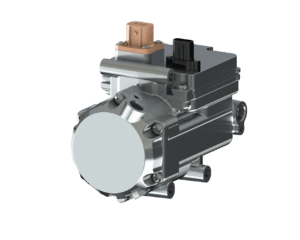

7. Air conditioning compressor

In vehicles with traditional combustion engines, the air conditioning compressor is mechanically driven directly from the engine crankshaft. In fuel cell-based systems, this is not possible—therefore, we use an electric air conditioning compressor that operates independently of the engine.

8. PTC heater

In combustion engine vehicles, the cabin is heated using waste heat from the engine. Hydrogen drive systems, being highly efficient, generate very little waste heat—therefore, thermal comfort is provided by an electric PTC (Positive Temperature Coefficient) heater. This is a safe, compact, and quick-acting heat source, ideally suited for the operating conditions of fuel cell vehicles.

9. Oil pump

In vehicles equipped with a hydraulic system, we use an electric oil pump, selected individually based on the system’s parameters. Unlike mechanical solutions, the electric pump operates independently of the traction motor, which increases operational efficiency.

FAQ

How does Ennovation ensure the safety of the hydrogen system and prevent leaks?

Our company places a strong emphasis on the safety of the hydrogen system at every stage of vehicle design and integration. To minimize the risk of leaks, high-quality hydrogen system connections and appropriate sealings are used already at the design stage.

Are hydrogen sensors installed in Ennovation vehicles, and how do they enhance vehicle safety?

Hydrogen sensors are a crucial part of the safety system in hydrogen-powered vehicles. Their primary function is to detect potential gas leaks as early as possible. In vehicles designed by Ennovation, sensors are placed in critical areas, such as beneath the driver’s cabin and near the fuel cell module. This strategic placement allows for quick detection of threats and immediate system response, significantly increasing safety for both the user and the vehicle.

How are the batteries cooled, and how does this affect their lifespan?

The batteries are equipped with a liquid cooling system that maintains optimal operating conditions for the lithium-ion cells. Cooling prevents overheating of the cells, which improves performance and extends their lifespan.

Does the battery system for hydrogen drives meet safety standards?

Yes. The systems we design include an advanced Battery Management System (BMS) that monitors cell operation and detects conditions such as thermal runaway and thermal propagation. These functions comply with the UN ECE R100.03 type approval requirements, ensuring a high level of safety.

What is the hydrogen storage system in the Ennovum H670 tractor made of?

The system consists of four Type IV tanks, constructed with an inner layer of HDPE (High-Density Polyethylene) reinforced with a carbon fiber composite. The tanks are located behind the driver’s cabin and operate at a nominal pressure of 700 bar.

What safety features do the hydrogen tanks have?

Each tank is equipped with an OTV (On-Tank Valve), which allows for refueling, supplying hydrogen to the fuel cells, and safely venting the gas in emergency situations. Additionally, thermal protection devices (TPRDs) are used to release hydrogen in case of excessive temperature rise.